Search Product

Search here for what you are looking for:

Send Inquiry

If you have any questions about our products, you can submit the form and we will contact you as soon as possible

Search here for what you are looking for:

If you have any questions about our products, you can submit the form and we will contact you as soon as possible

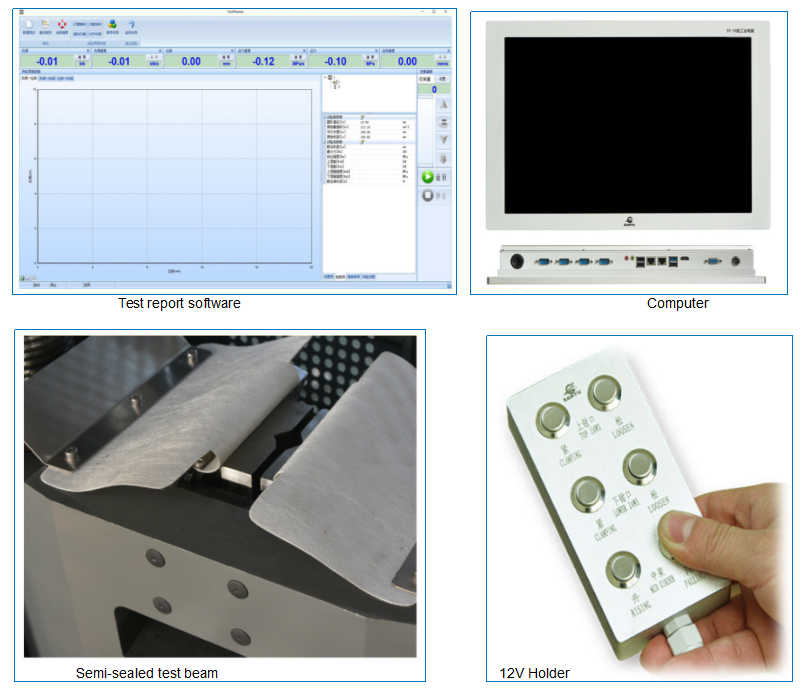

This testing machine for different materials or products, such as tensile, compression, bending, shear type test, can calculate the measured material tensile strength, yield strength and extension strength, modulus of elasticity, such as performance index, which can realize rate loading, such as rate, such as deformation, such as displacement, such as rate of strain rate, and other closed-loop control, the process of making materials or products can be qualified performance verification test.

The testing machine is six columns, double space structure, between the upper beam and the lower beam for stretching space, between the lower beam and the test table for compression space, the test space through the sprocket and lead screw rotation driven under the beam up and down to automatically adjust.The upper and lower beams are equipped with hydraulic control clamping jaws. Standard models are equipped with V-type and flat-type clamping jaws for clamping cylindrical samples and flat samples for tensile test.The bottom end of the lower beam of the standard model is equipped with the upper pressure plate, and the test table is equipped with the lower pressure plate with a spherical structure, which can be directly compressed test.

Standard: BS EN 10002-1, ISO 7500-1, ASTM A370

Technical Specifications:

WAWD-300B | WAWD-600B | WAWD-1000B | |

Max. test force | 300KN | 600KN | 1000KN |

Relative indication error | ±1% | ±1% | ±1% |

Effective range | 1%-100%F·S(Full range is not classified) | ||

Deformation measurement range | 1%-100%F·S | ||

Deformation shows the relative error of values | ±1% | ||

Displacement shows the relative error of values | ±1% | ||

Displacement measurement resolution | 0.001mm | ||

Stress rate control relative error | ±2% | ||

Displacement rate controls relative error | ±1% | ||

Strain rate control relative error | ±2% | ||

Force, deformation and displacement remain within the control range | 0.3%-100%F·S | ||

Force, deformation and displacement keep relative errors under control | ≦1% | ||

Lifting speed of middle beam | 240 mm/min | 240 mm/min | 240 mm/min |

700 mm | 700mm | 700mm | |

Maximum spacing of compression surfaces | 600 mm | 600mm | 600mm |

Piston stroke | 200 mm | 200mm | 200mm |

Maximum speed of piston movement | 120 mm/min | 100 mm/min | 100 mm/min |

Round sample clamping diameter | Φ10 mm –Φ32mm | Φ13 mm –Φ40mm | Φ14 mm –Φ45mm |

Clamping thickness of flat specimen | 0 mm -20mm | 0 mm -20mm | 0 mm -40mm |

Max. distance of fulcrum in bending test | 300 mm | 300 mm | 300 mm |

Up and down plate size | Φ150mm | Φ200mm | Φ225mm |

Overall dimension | 800x620x2000 mm | 900x700x2300 mm | 1050x800x2500 mm |

Dimensions of oil source tank | 800x600 x1600 mm | 800x600x1600 mm | 800x600x1600 mm |

Power | 2.2KW | 2.2KW | 2.2KW |

Weight | 2150KG | 2950KG | 3500KG |